Hard hats should be made of fiberglass or other advanced materials to ensure optimal protection for workers in hazardous environments. Fiberglass hard hats have emerged as the preferred choice due to their exceptional strength, durability, and comfort, making them essential safety gear in various industries.

Fiberglass hard hats offer numerous advantages over traditional materials. They are lightweight, reducing strain on the wearer’s neck and shoulders. Their impact and penetration resistance provide superior protection against falling objects and other hazards. Additionally, fiberglass hard hats are resistant to heat, chemicals, and moisture, ensuring longevity and reliability.

Historical Background of Fiberglass Hard Hats

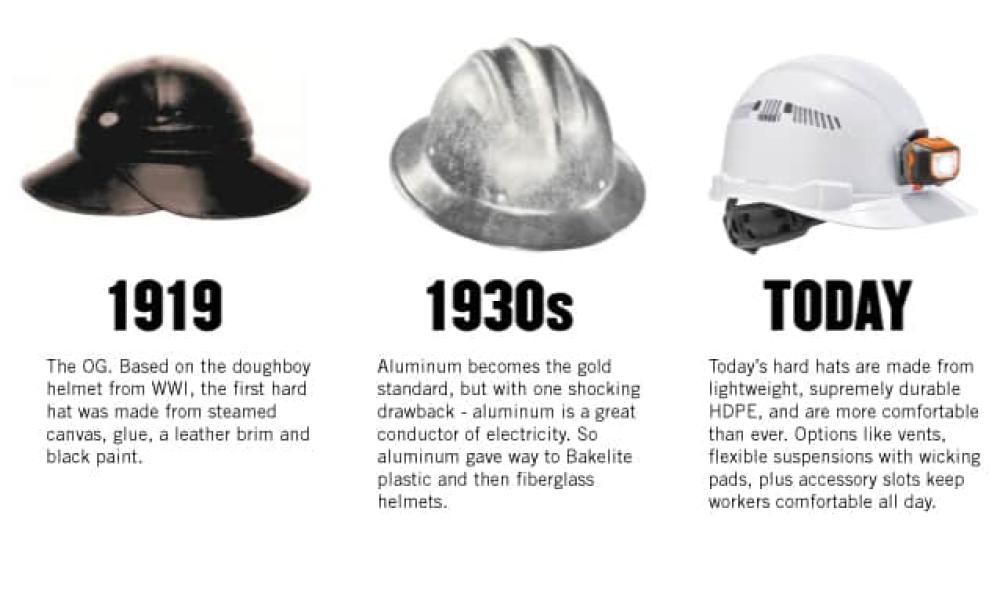

The evolution of hard hats from traditional materials like leather and metal to modern fiberglass began in the early 20th century. Concerns about worker safety in hazardous environments prompted the development of protective headgear. Initially, hard hats were made from heavy and cumbersome materials, limiting comfort and practicality.

The introduction of fiberglass in the 1950s revolutionized hard hat design. Fiberglass offered a unique combination of strength, durability, and lightweight properties, making it an ideal material for head protection. Early fiberglass hard hats, such as the MSA Skullgard, demonstrated superior impact resistance and penetration protection, significantly reducing head injuries in industrial settings.

Benefits of Fiberglass Hard Hats

Fiberglass hard hats offer numerous advantages over other materials, including:

- Strength and Durability:Fiberglass composites exhibit exceptional tensile strength and impact resistance, providing reliable protection against falling objects and blunt force trauma.

- Resistance to Impact and Penetration:Fiberglass hard hats are designed to withstand high-impact forces and resist penetration from sharp objects, safeguarding the wearer’s head from potential injuries.

- Lightweight and Comfortable Design:Fiberglass hard hats are significantly lighter than traditional materials, reducing fatigue and discomfort during extended wear. They feature adjustable suspensions and padding for a secure and comfortable fit.

Comparison of Fiberglass Hard Hats with Other Materials

| Material | Impact Resistance | Weight | Comfort Level |

|---|---|---|---|

| Fiberglass | High | Medium | Good |

| Polyethylene | Medium | Low | Fair |

| Aluminum | Low | High | Poor |

| Thermoplastics | Medium | Low | Good |

Fiberglass hard hats generally offer the best balance of impact resistance, weight, and comfort, making them the preferred choice for various industrial applications.

Question Bank: Hard Hats Should Be Made Of Fiberglass Or

Why are fiberglass hard hats better than other materials?

Fiberglass hard hats offer superior strength, impact resistance, and durability compared to other materials like polyethylene or aluminum.

What industry standards regulate fiberglass hard hats?

Industry standards like ANSI Z89.1 establish specific requirements for the design and performance of fiberglass hard hats to ensure worker protection.

How should fiberglass hard hats be properly maintained?

Regular cleaning, storage in a dry and cool environment, and periodic inspection for damage are essential for maintaining the integrity of fiberglass hard hats.